The Secrets of Casting

The secret is that there is none….. Because almost everything happens to be explained and the solutions of circumstance solve the majority of the problems.

It is necessary to return to the very nature of chocolate which is an intimate mixture of cocoa paste, cocoa butter, emulsifier, and sometimes aromatic products etc.

The average density of chocolate is about 1.2, slightly higher than the water. The chocolate when it is poured into mussels has been prepared beforehand so that it can crystallize harmoniously according to a precise cycle. It is sunk at a temperature of about 31 °, more or less according to the origin of the chocolate, the hand turn of the operator etc. As soon as it is sunk, the crystallization process will be implemented and we will put the mold to the cold to finalize the whole thing. During the crystallization and the drop in temperature, the chocolate will freeze into a compact and hard mass.

1 • During this operation, the chocolate will undergo a variable volume withdrawal of more or less 1%. This indentation is the fundamental variable that will allow the demoulding. The chocolate after its withdrawal will therefore be overall smaller than the housing in which it was sunk and this will therefore allow in principle to take it out of its moulding pocket.

2 • Second fundamental parameter: the body of the mould. All the world's mussels, with no exceptions, have draft angles that facilitate the extraction of the molded product. If the mould geometry has negative draft angles, it will be retention areas that prevent the release of the mold or produce an incomplete release, leaving parts that break and remain in the mould.

3 • Air traps: These are areas where the chocolate will not be able to take place because air pockets are already there. It is necessary to ensure the correct filling. The universal method is the pressure forcing (3OO kg/cm2 for injection moulds of plastic or metal…) Some kg/cm2 for jewelry wax injection molds in silicone molds. For chocolate This is not possible so you have to either force the chocolate by hand, using a brush for example, or centrifuge on 3 axes, or have a mold that by its conception takes into account this delicate problem. A good tapping at 5O Hz will help remove the bubbles in the bottom of the mold as well as the bubbles contained in the chocolate.

4 • Final appearance: We look for an aesthetic aspect and only the mould will make chocolate its own surface condition qualities, finishing edges etc.

These 4 fundamentals explain the following problems:

Silicone elastomer Molds. This material is relatively supple, so during crystallization, it accompanies the chocolate and continues to adhere to it. No normal autodémoulage: the part of its housing must be extracted with the risk of breakage of a relatively fragile material. In addition to its permanent contact, a thin layer of cocoa butter continues to adhere to the walls after demoulding and the final product does not have the brightness and brilliance given for example by a traditional polycarbonate mould to the mirror-polished surface. However a light little brush stroke in pork hair will make all its luster to chocolate. We use laboratory equipment to avoid all the bubbles and ensure an absolute fidelity of the reproduction of the model.

Milled moulds by numerically controlled machine tool. Universal method of manufacture, price proportional to the complexity of the subject, obligation of scrupulous management of the remains, considerable work of finishing of the surface states carried out most of the time by hand to erase the traces of the tools of Milling, then finishing coating by electrolytic repository of chromium, copper etc. It is the daily work of manufacturers of industrial moulds, which moulds, given their considerable prices, must amortize the investment tooling by mass production.

"Amateur" strawberry mussels do not have a draft because the tools to do so are very expensive and very rare. Therefore use of straight strawberries and inability to make details of the order of 1/1Oe of MM because it requires equipment whose prices are exorbitant. This limits the production to basic moulds of fairly average quality.

Thermoformed moulds made of PVC crystal, polystyrene-shock, polyethylene etc. These are the products of our daily life since the years 1950. Food containers, blisters, protective and presentation packaging etc… They are intended for use "one shoot", one opens and one throws. The big advantage of this type of product is the cost price, relatively simple material, and intensive productivity. This type of mussels exists for chocolate because they are not expensive, but their lifespan is very low. The restitution of fine and precise details is impossible because it would require high-finish models and high-pressure thermoforming; We return to square one: price of the tool important to be amortized on large series which is not viable for ordering a few hundred personalized chocolates. These thermoformed parts are not of constant thickness, the stretching areas are thinner and you may experience draping problems depending on the geometry of the model.

Our solutions

All these details lead us to set up an "ideal" mould

Certified alimentarity — Rigidity — transparent mould to follow the final indentation and tack — mastered surface States — necessary and sufficient remains — management of air pockets — Finesse submillimetric details — very competitive prices — Production times less than the week.

We offer two SOLUTIONS

1 • Highlight 2.5 D positive, mixed, hollow

2 • Proportional 3d emphasis

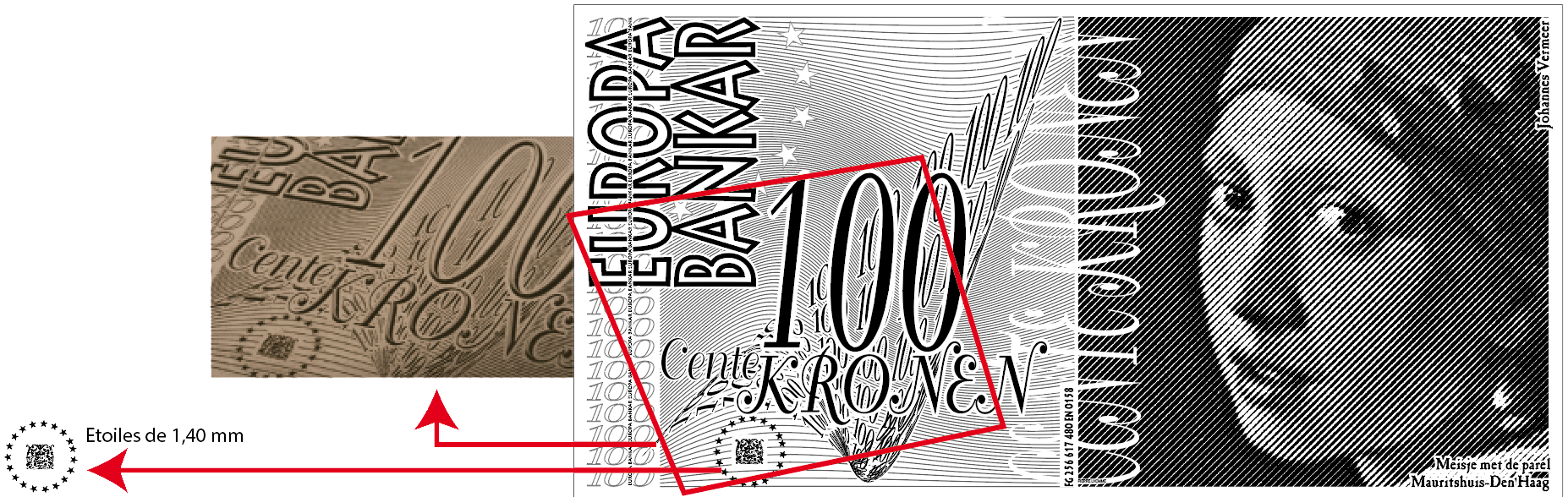

This photo of a chocolate bar gives a clear idea of the possibilities of this process deposited at the National Institute of Industrial Property.

Mould made of acrylic resin, draft on all plots, finer details of 1OO microns (o 1 mm), heights varying from O, 1 mm — o,35 mm proportional to the width of the motifs drawn in 2d. Satin surface States, drawing on the length of 1.6 mm, final thickness of about 5 mm depending on the filling rate of the mould.